Horizon Hydrogen

Ft.McKay, AB

CNRL

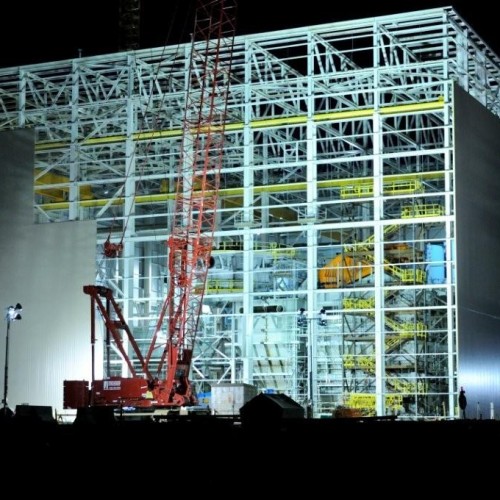

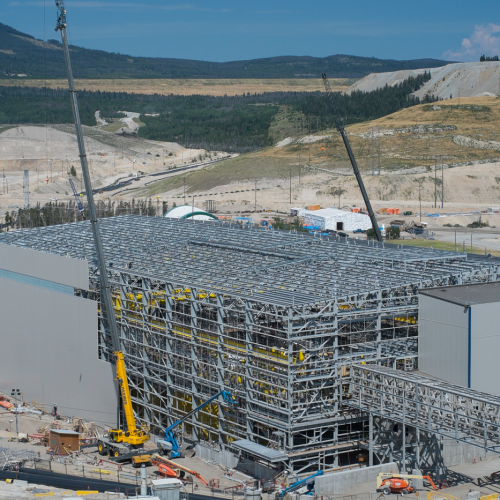

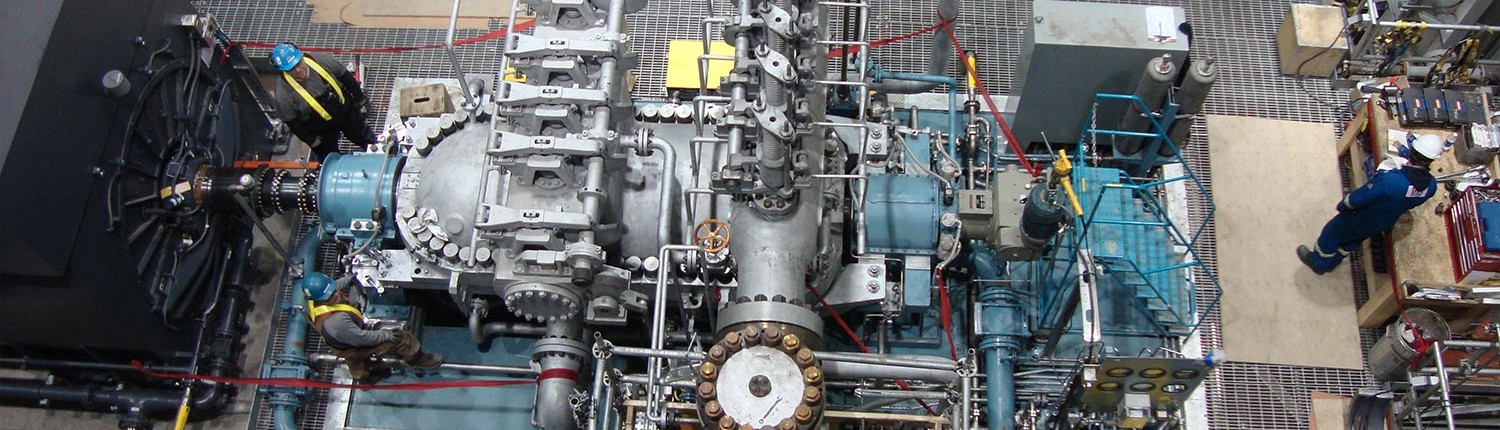

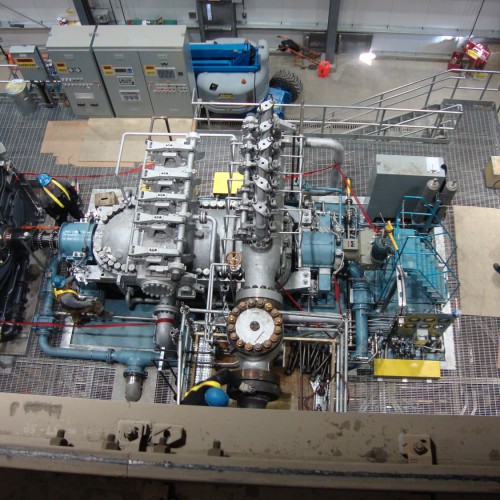

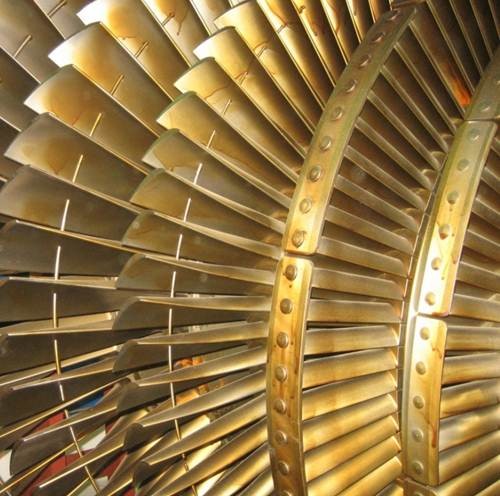

The CNRL Horizon H2 Plant is a 144,000 MMSCFD plant including a reformer, 2 compressors and a PSA facility.

For this project, JV Driver was the general contractor providing civil, structural, mechanical, piping, electrical and finishes. Our scope included over 859 metric tons of support steel, 21 modules, 1,000 concrete piles, 3,500 cu. meters of concrete foundations, 50,000 ft. of piping, construction of the reformer and pressure parts.

Due to high performance, and a record of completing jobs on schedule, more work was continually added to our scope. We took over several of the electrical scopes of work during the project, at which time we successfully mobilized over 150 electricians in less than 3 weeks.

The project involved a large amount of alloy welding which was completed with no rework and a weld repair of less than 1%. Further, our scope was completed with 0 Lost Time Accidents and a TRIR of 0.6. Adding to the Safety and Quality accomplishments, during the project JV Driver broke Technip’s world record for most tubes stabbed in 1 day (48 in a single day).