Krupp—Kearl Lake

Krupp

Krupp Lift

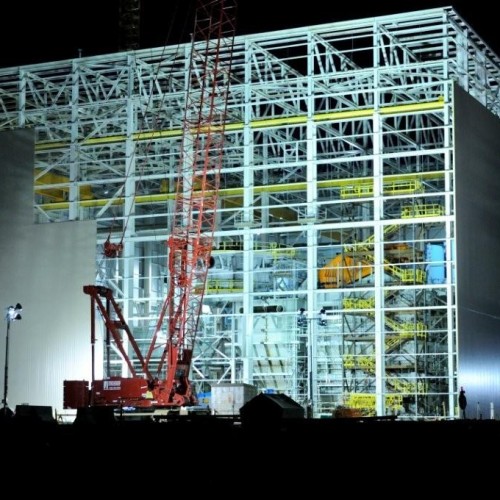

JV Driver completed the Structural and Mechanical erection of the Slurry Prep Plant and the OPP Conveyor System for the Crusher and Surge Bin. The 4 story structure is a 64,200 square foot plant with a 0.7 km conveyor line. JV Driver’s scope includes the piping, mechanical, civil and structural. The project incorporates over 30,000 inches of pipe of varying commodities and 1,900 tonnes of steel. The Mechanical equipment includes a 500 ton crane, a 320 ton crane, two 90 ton cranes, a zoom boom, skid steer, 3 AWP’s, a grader, loader, sanding and fuel truck.

In addition to the construction scope of work we are providing site fueling and road maintenance services to our client.

To date there have been Zero Lost Time Accidents.

Krupp—Kearl Lake

Krupp

Krupp Lift

JV Driver completed the Structural and Mechanical erection of the Slurry Prep Plant and the OPP Conveyor System for the Crusher and Surge Bin. The 4 story structure is a 64,200 square foot plant with a 0.7 km conveyor line. JV Driver’s scope includes the piping, mechanical, civil and structural. The project incorporates over 30,000 inches of pipe of varying commodities and 1,900 tonnes of steel. The Mechanical equipment includes a 500 ton crane, a 320 ton crane, two 90 ton cranes, a zoom boom, skid steer, 3 AWP’s, a grader, loader, sanding and fuel truck.

In addition to the construction scope of work we are providing site fueling and road maintenance services to our client.

To date there have been Zero Lost Time Accidents.

Shell Albian Sands

Fort McMurray, Alberta

Shell

The AOSP Expansion project was a 4 Billion dollar expansion of the existing Shell Albian facility. It included the Jackpine mine, new extraction, tailings, froth and utilities facilities. Phase 1 ran from Q3 2006 to Q2 2010.

JV Driver was the General Contractor for the extraction and tailings portion of this project, responsible for the completion of all aspects of the project, including civil, mechanical, structural, tankage, electrical, and instrumentation.

Our scope was approximately 8 million man-hours. JV Driver was involved with the entire scope of this project, including both labour strategies and constructability. The project was completed meeting schedule and budget milestones, while ensuring quality and safety, with less than 0.5% rework, productivity over 1.15 and no Lost Time Incidents.

Shell Albian Sands

Fort McMurray, Alberta

Shell

The AOSP Expansion project was a 4 Billion dollar expansion of the existing Shell Albian facility. It included the Jackpine mine, new extraction, tailings, froth and utilities facilities. Phase 1 ran from Q3 2006 to Q2 2010.

JV Driver was the General Contractor for the extraction and tailings portion of this project, responsible for the completion of all aspects of the project, including civil, mechanical, structural, tankage, electrical, and instrumentation.

Our scope was approximately 8 million man-hours. JV Driver was involved with the entire scope of this project, including both labour strategies and constructability. The project was completed meeting schedule and budget milestones, while ensuring quality and safety, with less than 0.5% rework, productivity over 1.15 and no Lost Time Incidents.

Highland Valley Copper

Logan Lake, B.C.

Teck

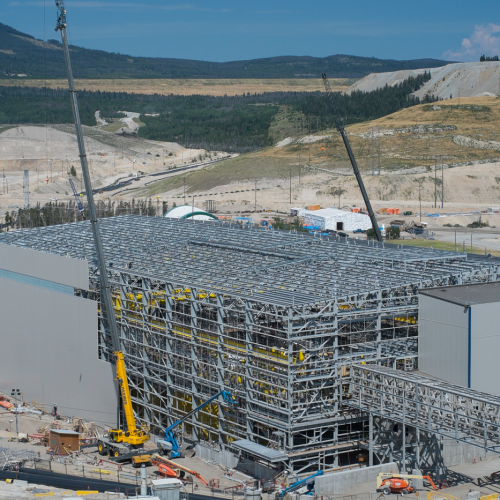

JVD completed the construction contract for Highland Valley Copper, the contract was carried out through a Joint Venture between Fluor Canada and JVD.

Located approximately one hour from Kamloops B.C., Highland Valley Copper is an existing open pit copper molybdenum operation. The plant has a current nominal production rate of 125,000 tpd of ore. The project scope included the installation of a new pebble crushing facility, upgrades in the existing grinding building, a new floatation facility, upgrades to the existing regent area and a new 138KV transformer. The project maintained a crew of approximately 700-900, consisting of Civil, Structural, Mechanical, Piping and Electrical disciplines and over 1,000,000 direct man-hours.

Highland Valley Copper

Logan Lake, B.C.

Teck

JVD completed the construction contract for Highland Valley Copper, the contract was carried out through a Joint Venture between Fluor Canada and JVD.

Located approximately one hour from Kamloops B.C., Highland Valley Copper is an existing open pit copper molybdenum operation. The plant has a current nominal production rate of 125,000 tpd of ore. The project scope included the installation of a new pebble crushing facility, upgrades in the existing grinding building, a new floatation facility, upgrades to the existing regent area and a new 138KV transformer. The project maintained a crew of approximately 700-900, consisting of Civil, Structural, Mechanical, Piping and Electrical disciplines and over 1,000,000 direct man-hours.

Horizon Extraction Plant

Ft.McKay, Ab

Canadian Natural Resources Ltd.

“The CNRL Extraction Plant consists of two (2) primary separation cells, flotation cells, twenty (20) pipe rack modules, hot water facility, electrical substation, and emergency dump sump.

JV Driver was involved in this project from the early stages of development providing constructability support, labour strategies and construction services. Our scope was as the general contractor, providing civil, structural, piping and mechanical services. We also provided the off-site fabrication and module assembly for this project. JV Driver’s scope included over 1,000,000 craft man-hours.

Having been involved with the entire scope of work, JV Driver was engaged for the entire 4 year life of the project, during that time there were no changes in the Productivity Units. To add to the success, JV Driver was the first to turn over a Silo for commissioning, and did so with no rework and a weld repair of less than 1%. The project was completed on time and on schedule with no Lost time Incidents. ”

Horizon Extraction Plant

Ft.McKay, Ab

Canadian Natural Resources Ltd.

“The CNRL Extraction Plant consists of two (2) primary separation cells, flotation cells, twenty (20) pipe rack modules, hot water facility, electrical substation, and emergency dump sump.

JV Driver was involved in this project from the early stages of development providing constructability support, labour strategies and construction services. Our scope was as the general contractor, providing civil, structural, piping and mechanical services. We also provided the off-site fabrication and module assembly for this project. JV Driver’s scope included over 1,000,000 craft man-hours.

Having been involved with the entire scope of work, JV Driver was engaged for the entire 4 year life of the project, during that time there were no changes in the Productivity Units. To add to the success, JV Driver was the first to turn over a Silo for commissioning, and did so with no rework and a weld repair of less than 1%. The project was completed on time and on schedule with no Lost time Incidents. ”

Oil and Gas

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Pellentesque risus diam, elementum sed posuere vel, bibendum maximus lorem. Praesent eros quam, volutpat in orci vitae, imperdiet scelerisque nulla. Quisque at interdum metus. Fusce ultricies sit amet risus ultricies porta. Duis urna est, congue eget ipsum in, rhoncus egestas sapien. Nullam non dignissim diam, sollicitudin sagittis lectus. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Mining

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Pellentesque risus diam, elementum sed posuere vel, bibendum maximus lorem. Praesent eros quam, volutpat in orci vitae, imperdiet scelerisque nulla. Quisque at interdum metus. Fusce ultricies sit amet risus ultricies porta. Duis urna est, congue eget ipsum in, rhoncus egestas sapien. Nullam non dignissim diam, sollicitudin sagittis lectus. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Power

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Pellentesque risus diam, elementum sed posuere vel, bibendum maximus lorem. Praesent eros quam, volutpat in orci vitae, imperdiet scelerisque nulla. Quisque at interdum metus. Fusce ultricies sit amet risus ultricies porta. Duis urna est, congue eget ipsum in, rhoncus egestas sapien. Nullam non dignissim diam, sollicitudin sagittis lectus. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Petrochem

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Pellentesque risus diam, elementum sed posuere vel, bibendum maximus lorem. Praesent eros quam, volutpat in orci vitae, imperdiet scelerisque nulla. Quisque at interdum metus. Fusce ultricies sit amet risus ultricies porta. Duis urna est, congue eget ipsum in, rhoncus egestas sapien. Nullam non dignissim diam, sollicitudin sagittis lectus. Lorem ipsum dolor sit amet, consectetur adipiscing elit.