Innovation – The Mity Mite

The Mity Mite Pipe Puller Built In The USA by JV Driver Fabricators

The innovative Mity Mite is a one-of-a-kind expansion joint compression tool used for pipe pulling and the installation of concrete pipe, concrete box culverts, precast concrete steel cylinder pipe, and ductile iron pipe. It is designed, manufactured, and tested out of our Phoenix, Arizona fabrication facility.

The Mity Mite was created as the result of a market gap in the construction industry when it came to joining large sections of concrete, steel, and plastic pipe over 40 years ago. There simply wasn’t anything that could effectively join large sections of pipe that weighed up to 40 tons and were as large as 144” in diameter. Hence, the Mity Mite Pipe Puller was born, the most cost-effective and time-saving product on the market for pipe pulling.

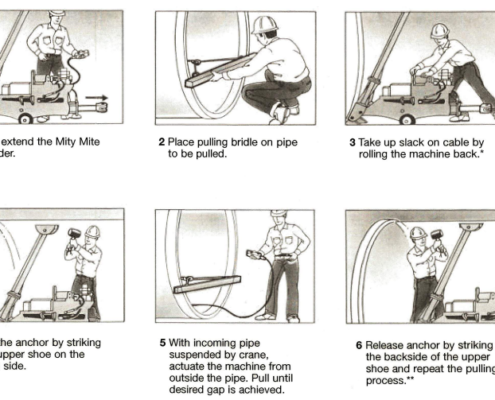

But how does it work? Simply put, it wedges on either side of the pipe and a hydraulic cylinder pulls them together. Here’s the step-by-step pulling process:

As you can see in panel 5, once the Mity Mite is set up on the pipe, the pulling process is automated remotely to the desired gap. This is the main advantage of the patented device, other than the ease of set-up and use. It allows the user to remain outside of the pipe, away from the pulling being carried out, at a safe and secure distance. It is also why the patented device is superior over the traditional “winch and cable” method.

All of this results in increased speed, efficiency, safety, and cost savings when dealing with pipe pulling.

If you’re interested in the innovative Mity Mite, please contact us.

JV Driver Fabricators

info@jvdriver.com