Highlights

| Over 20 Years in the field Lost Time Accident free | |

| Multiple Construction Owners Association of Albert (COAA) Awards for Best Practices and Safety Implementation | |

| 2009 | Shell President’s Award |

| 2009 | Golden Nugget Safety Award from Imperial Oil |

| 2013 | Recordable Incident Free Maintenance Operation at Imperial Oil’s Kearl lake facility |

| 2005–2008 | Work Safe Alberta “Best Safety Performer” (award was discontinued in 2009) |

Oil & Gas Sector Projects

Nabiye

Cold Lake, Alberta

Imperial Oil Resources

JV Driver has been awarded the new steam-generation, bitumen-processing and water treatment facilities to support the In-Situ oil extraction process in Cold Lake. JVD’s scope of work includes earthworks, foundations, structural, piping, mechanical, modules, pipe and steel fabrication. The mechanical equipment being used is 2 GE Turbines, 2 TIWW HRSGs, one TIWW OTSG, field erected tanks and an Ecodyne Hot Lime Softeners. Additional services provided are procurement of bulk materials and responsibilities as prime contractor.

JVD Fabricators also completed all fabrication and module construction for this project

Carmon Creek

60 KM NE of Peace River

Shell

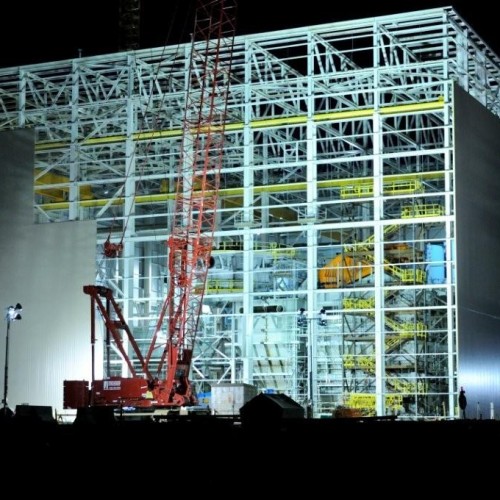

JV Driver has been awarded the Carmon Creek Project, vertical well steam drive facility that will produce up to 80,000 barrels per day of bitumen (12,600 cubic meters). The Scope includes all; Civil, Structural, Mechanical, Piping Electrical and Instrumentation with constructability and workface planning already in progress. The project also involved the installation of 3, 200+ MW Gas Turbine Generators and 3 HRSG Boilers for the Steam Injection System.

Constructability for the project began in May 2013.

Shell Albian Sands

Fort McMurray, Alberta

Shell

The AOSP Expansion project was a 4 Billion dollar expansion of the existing Shell Albian facility. It included the Jackpine mine, new extraction, tailings, froth and utilities facilities. Phase 1 ran from Q3 2006 to Q2 2010.

JVD was the General Contractor for the extraction and tailings portion of this project, responsible for the completion of all aspects of the project, including civil, mechanical, structural, tankage, electrical, and instrumentation.

Our scope was approximately 6.5 million man-hours. JVD was involved with the entire scope of this project, including both labour strategies and constructability. The project was completed meeting schedule and budget milestones, while ensuring quality and safety, with less than 0.5% rework, productivity over 1.15 and no Lost Time Incidents.

JVD Fabricators completed all fabrication and module construction for JVD’s scope of work, including 22 Extraction Modules, 9 Tailings Pump Houses and 49 Froth Modules.