Typically, hot work is monitored with fire watch personnel who check for hot spots by making visual checks and by safely touching the work surfaces. This monitoring would take place for a minimum of one hour in a building's interior and/or exterior after hot work was performed. If a hot spot was located the team would cut and expose the surface and wet down the area.

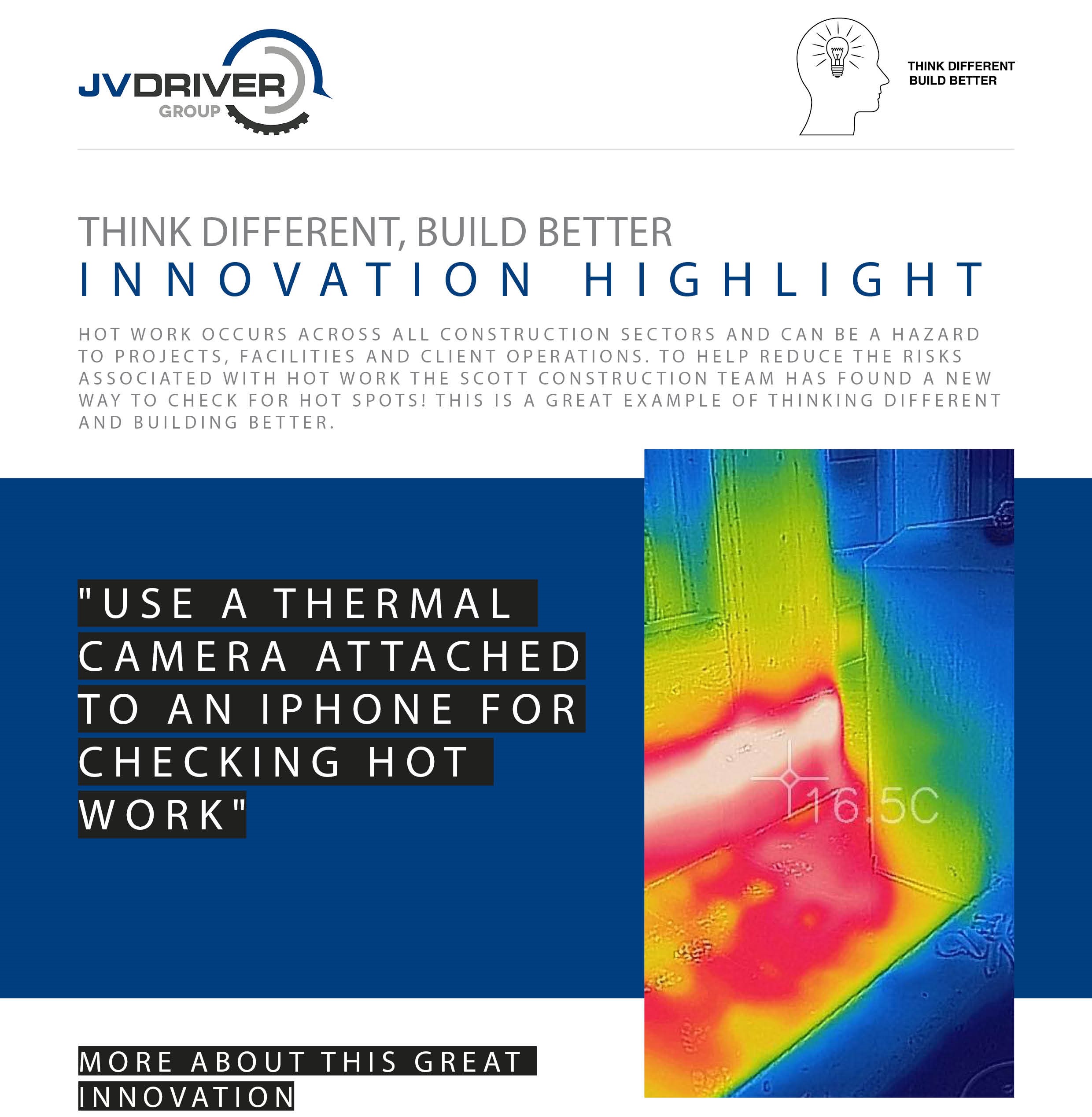

By thinking differently, they have armed the fire watch team with an additional tool for monitoring areas and locating hot spots. With the use of the thermal camera the team can check the background temperature of the surrounding area then compare this to the area where hot work was completed. If you see a difference in temperature, then the team would need to investigate further. This could lead to the earlier discovery of smoldering hot spots. Earlier discovery would allow for action to be taken sooner and possible damage could be avoided.

Innovative thinking has allowed a new tool to be utilized which helps eliminate damage and improve overall safety of the project. Thinking Different and Building Better - A great innovation from Scott Construction!