State of the Art Fabrication

Through its fabrication enterprise the JV Driver Group offers a wide range of fabrication capability with large capacity, state of art facilities and strategic locations. We always think about being exceptional at what we do and at the JV Driver Group we have re-imagined industrial fabrication. We do what others can’t, due to innovations in facilities and approaches. We conducted extensive research, visited facilities around the world and then embarked on a large investment program that has resulted in state-of-the-art facilities that allow for the most productive workflow. Simply stated, our new facilities and tooling are among the best and most modern in the world. In fact, the investment in state-of-the-art capability continues with the opening of our new painting facility at DF Barnes Fabricators in January 2016.

Our product lines include steel and pipe fabrication, module construction, stationary equipment, boilers, exchangers, sign and bridge fabrication, high value add marine equipment.

With over 420,000 square feet of fabrication space coupled with 100 acres for module erection and locations in Edmonton, Houston, Phoenix and Newfoundland we offer a capability and geographic reach that can address all your fabrication needs.

Please see below, the members of the JV Driver Fabrication Enterprise: JV Driver Fabricators and DF Barnes Fabricators.

Highlights

JV DRIVER FABRICATION COMPANIES

A Sample of our Fabrication and Module Projects

Horizon Recovery Plant

Our team has completed the Horizon Recovery Plant and CO2 Recovery Unit Modules for Air Liquide. The project included 20...

Nabiye

Our team was awarded a total of 41 modules (35 Piperacks, 6 Equipment modules with fully welded structural bases). This...

Kearl Lake Modules

Our team was awarded the Reassembly of 77 Fully Welded Korean Built process modules destined for Imperial Oil’s Kearl Lake...

Shell Pump Houses

Our team was awarded 3 Pump houses measuring 18 meters in length by 7 meters in width and 7.4 meters...

Sobeys Steel

Our team completed 55 tons of steel fabrication for the new Sobeys Storefront in Sherwood Park Alberta. The project was...

Firebag 3

Firebag utilizes in-situ production, steam-assisted gravity drainage (SAGD), at their Northern Alberta facility. Firebag 3 is the third phase of...

Walmart Steel

Our team completed 25 tons of steel fabrication for the new Walmart Medicine Hat Alberta. The project was completed on...

Jackfish SAGD

Our team provided complete services from EDS constructability through mechanical completion. The services provided also included the completion and installation...

Keg Steel Fabrication

Our team completed 45 tons of steel fabrication for the new Keg Steakhouse in the beautiful Windemere neighborhood in Edmonton...

CNRL Horizon

Our team completed the pipe fabrication and module construction for all aspects of the Horizon Extraction Plant. The scope consisted...

Steel Fabrication

Our team completed 171 tons of the steel fabrication for the Orchard School construction in Edmonton Alberta. The project was...

Module Construction

Our module yards are purpose built for erection of the largest transportable modules in each region and any other assemblies our clients need. This includes: Pipe Rack Modules, Horizontal Process Modules, Vertical Process Modules, Pump Houses, Well Pads, Compressor Skids, OTSG and HRSG Stack components and Stair Towers.

JV Driver Fabricators’ Nisku facility has free and clear access to the High Load Corridor in Alberta, while JV Driver Fabricators’ Phoenix facility has direct access to the interstate, providing our clients the best available access to shipping routes across North America.

Our material control in the module yard uses the latest in RFID technology to ensure that all our clients’ materials are easily located at the push of a button, minimizing handling time and risk of material loss resulting while maximizing cost savings.

Large or small, JV Driver has the yard capacity to handle all of our clients’ module fabrication needs.

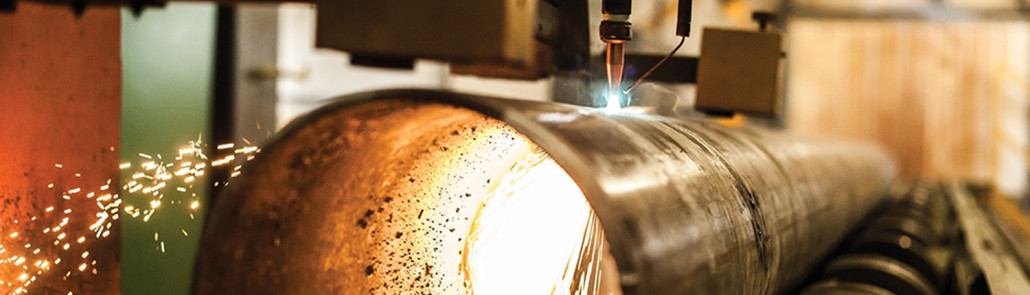

Pipe Fabrication Capability

With 4 pipe fabrication facilities across North America in Edmonton, Phoenix, Houston and Newfoundland, the JV Driver Group is able to execute piping projects of any size. Utilizing the latest in lean manufacturing, cutting edge software and an innovative “pull system”, these facilities are leaders in the industry. Able to fabricate all diameters, wall thickness and configurations, for carbon, stainless and exotic alloys, these facilities work together to provide the exceptional value possible, while maintaining leading safety and quality performance.

The JV Driver Group uses highly advanced, internet-based production software, we provide integrated material management solutions, warehousing, quality control management, complete production monitoring and reporting, from the cradle to grave on all projects. This allows for real-time reporting and establishes transparency while increasing value to our clients.

Employees are fully trained and skilled in the art of LEAN fabrication. This reduces the amount of work-in-progress and results in significantly shorter delivery times to our clients. With this approach to pipe fabrication, our facilities surpass all others in our industry.

Our people are second to none, and we prove it by the ground-level innovation that workers provide in our weekly innovation meetings. This is a forum where workers can suggest safer and more efficient solutions to add value to our projects. Engaging our employees this way allows us to dramatically increase the production levels through improvements in safety, quality and efficiency.

THINK SAFE, WORK SAFE, BE SAFE ®

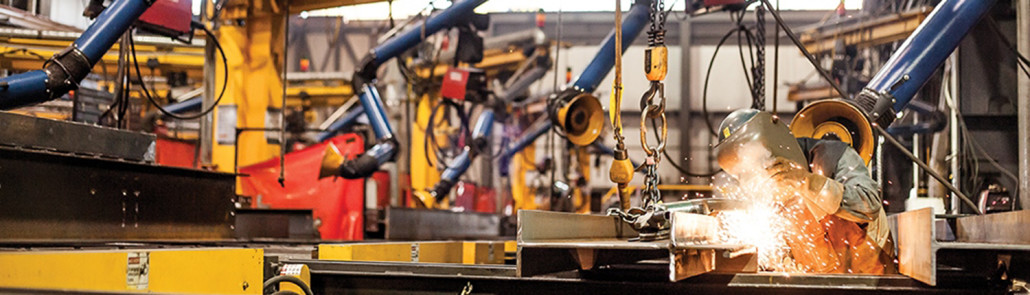

Steel Fabrication Capability

Our structural steel fabrication facilities in both Edmonton and Phoenix are the result of years of research, planning and multiple facility visits around the world. Incorporating the most innovative steel fabrication processes and equipment in North America, including state of the art CNC processing equipment and innovative material management, RFID and GPS tacking, lean manufacturing and ground level innovations, our facilities are able to produce over 20,000 M/T of steel per year.

Our LEAN manufacturing shops are optimized at every step allowing materials to move seamlessly through the production process. Aided by state of the art conveyance systems and integrated material handling programming allows for minimal human interaction in material movement.

Supported by senior management, workers are empowered to create innovative solutions to any problems. These ideas lead to major efficiency gains, resulting in savings for our clients.

Stationary Equipment Capability

Through JV Driver Fabricators in Houston, the JV Driver Group is able to provide complete Exchanger and Boiler services, including Tube Repair, Bundle Extraction, Furnaces and Fabrication of Shell and Tube Bundles. The Group offers the restoration of efficiency in heat exchangers, steam condensers, re-boilers, product coolers, fin-fan coolers, charge air coolers and chillers. Additional services include: tube sheet restoration, tube cleaning, feed-water heater repairs, bundle fabrication and re-tubing, Repair Snuff and Steam Headers, Replace Burner Management Systems, Replace Tube Sheet/Skin Repairs, Bolting, Duct Work Repairs, Header Piping Repairs, Leak Repairs.

The Group offers the restoration of efficiency in heat exchangers, steam condensers, re-boilers, product coolers, fin-fan coolers, charge air coolers and chillers. The JV Driver Group also offers tube sheet restoration, tube cleaning, feed-water heater repairs, bundle fabrication and re-tubing.

Bridge and Overhead Tubular Sign Structures

Through our Phoenix location, JV Driver Fabricators is a leader in the fabrication of specialty construction products including bridge structures and tubular sign structures. Our facility is certified by the American Institute of Steel Construction (AISC Certified Building, Bridge and Bridge Component Fabricator) for Major Steel Bridges with Fracture Critical Endorsement and the Standard for Steel Building Structures.

Some of the bridges we completed include:

- Santa Fe Bridge

- San Tan Vista Trail Bridges Phase 1

- Design-Build of Pedestrian Bridge on

- Canyon Rim Trail

- Otay Valley Regional Park Trail

- Stage Santa Fe Acequia Trail

- 1-17 Pedestrian Bridge over CAP

- Joe’s Trail at Saratoga De Anza

Connect Concrete Pipe – The Mity Mite

In the past, combining two concrete pipes used to be time-consuming and expensive, but with the Mity Mite, it is now both easy and profitable!

The patented device was created over 40 years ago, developed as a response to the construction industry’s need to join large sections of concrete and plastic pipe and can pull weights up to 30 tons or diameters up to 144″. Designed, manufactured and tested at our Phoenix, Arizona fabrication facility, these devices are the most cost-effective machines for joining concrete pipe on the market.

The Mity Mite comes with a complete parts inventory, which assures your crews the best in quality, service, and parts availability when you need it most.