Over 80 years in Marine

Through DF Barnes, the JV Driver Group offers marine and offshore repair and maintenance services around the world. In addition, we manufacture high-value add equipment for the marine industry in our state-of-the-art fabrication and painting facilities located in St. John’s, Newfoundland.

Another member of the of our Group is Extreme East Rigging Services that has been manufacturing iceberg and heli-deck landing nets for offshore oil platforms for decades. They also perform lifeboat davits testing.

Established in 1932, DF Barnes couples deep experience with the most modern tools and techniques to address a client’s needs. From emergency repair to planned retrofits we have the capability to return your assets to full operation reliably, quickly and cost-effectively.

Through the years we have manufactured many complex pieces of marine equipment, including launch recovery vehicles for oil and gas rigs. Our advanced approaches, including LEAN manufacturing, make us leaders in the unique needs of the marine and offshore industry. Quite simply we are world class.

Highlights

JV DRIVER MARINE COMPANIES

Marine Sector Experience

Rigging Services

Extreme East Rigging Services has been meeting the marine industries rigging requirements for decades. Projects include the supply of iceberg...

PGB’s

DF Barnes Fabrication successfully completed 7 permanent guide bases (PGB) for OneSubsea. OneSubsea delivers integrated solutions, products, systems and services...

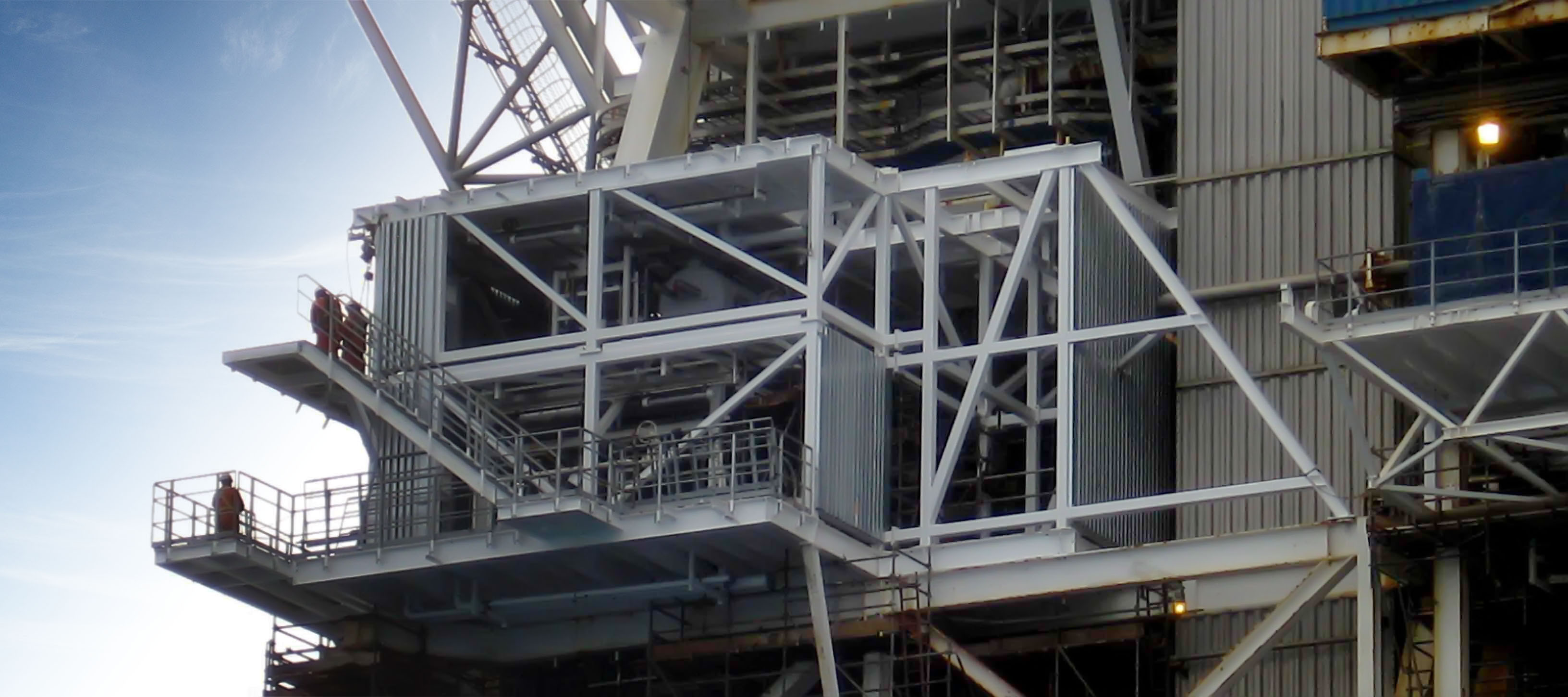

Large and Small Refits

We have successfully completed several large and small refits on a number of rigs including: Henry Goodrich, GSF Grandbanks, Rowan...

Green Wall Repair

The Stena Carron required emergency repairs offshore as a result of cracks found in the hull and bulwark structure. DF...

The Atlantic Hawk

We fabricated and installed a new crane pedestal and reinstalled the existing crane. This work included all hydraulic and electrical...

The Maersk Detector

As a result of a collision with an oil rig, this D-Class supply vessel sustained substantial damage to the port...

Ship Repair

With over 80 years of operations, DF Barnes Services has successfully completed hundreds of small and large scale projects and provided a wide variety of products and services to the marine, industrial and offshore industries. Our experience and the ability to offer emergency and planned repair and maintenance around the globe make us an industry leader. This experience also allows us to be creative and flexible including the ability to design solutions that can be performed while the ship or platform is in-transit. With that kind of experience and know-how you can rely on us to provide timely, high quality, good value solutions.

Rig Maintenance

Since 1932, the company has been in the business of maintaining the rigs, platforms and support vessels that operate in the North Atlantic Ocean – one of the harshest ocean environments on earth. Being in business this long requires a commitment to our clients that is unparalleled as evidenced by repeat business that has gone across generations. With our strategically located facilities we are able to be where our clients need us – reliably and quickly. In addition, long term relationships requires a commitment to always looking for better ways to do things and With our demonstrated, systematic approach to innovation including investment in state-of-the art facilities and techniques we do just that. Quite simply we have been industry leaders for a long time and we are constantly evolving so we remain so.

Fabrication

The JV Driver Group is manufacturing advanced mechanical and hydraulic equipment for the world’s largest marine and offshore companies. With the continuous production of LARS, TGBs, and traction winches, we established efficient manufacturing processes including LEAN Manufacturing principles. These standardized, formal procedures enable the company to manufacture predictably at lower cost while maintaining high quality. These lower costs are passed on to provide even better value to our customers.