Construction Innovation

This list of Construction Innovation showcases the JV Driver Group’s innovation at a few levels and types; anything from technology innovations that enable projects, team and people to be more effective at site or in our offices; advancements in process that takes waste out of our systems and finally innovations is safety that allow our team to deliver world-class results and get our people home safely every single day!

This is just a sample of the construction innovations the have been the foundation of the JV Driver Group’s success, have a look, if you have any questions please let us know. Construction and Innovation are two of our favorite things!

2019 Innovation of the Year – The Scott Construction Mental Health Committee

Read MoreSpotter Flag Many of the JV Driver Group’s construction projects and facilities utilize operated equipment on a regular basis and ensuring zero harm when operating this equipment is a priority for all teams. With this priority in mind, and a little TDBB thinking the team developed the spotter flag! When operating heavy equipment it can…

Read MoreStephanie tells us about her idea for installing an HDPE trans-mission main underneath the Englishman River with a 750mm casing. Tell me a little about how this innovation got started. Stephanie Ridenour: The permit for in-stream works (August 1 – September 15th) was a major requirement we had to work around. Once we began work in…

Read MoreLoading and unloading trailers occurs every day across the JV Driver Group. Traditionally, you would require a 6 foot step ladder securely tied to the trailer, or additional manpower to hold the ladder prior to accessing the deck. The IDL team has created access steps that remove the need for a ladder and allow for…

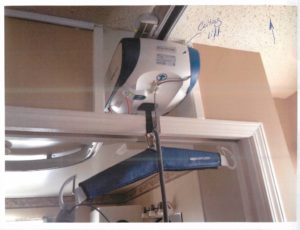

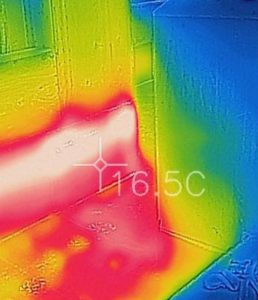

Read MoreTypically, hot work is monitored with fire watch personnel who check for hot spots by making visual checks and by safely touching the work surfaces. This monitoring would take place for a minimum of one hour in a building’s interior and/or exterior after hot work was performed. If a hot spot was located the team…

Read MoreCrew engagement at its best! The safety sponsor innovation drives engagement with the crew and gets them involved and participating in the safety program and the safety of their teams. This innovation was developed at the workface by the people actually executing the work. The safety teams work with the daily safety sponsor and make…

Read MoreThis is a shout out to the teams and people who have been driving our innovation from the very beginning. In this example, we remember back to the days of our paper systems, paper processes and the people who helped us break free. Do you remember when pay stubs were printed and handed out? One…

Read MoreBe Innovative, Build Great Things and Take Care of Each Other are 3 of the JV Driver Group’s Core Values. This innovation from our fabrication team at DFB Driver lives these values! This tool makes our fabrication team faster and more productive while also providing a training tool that can be used with apprentices who…

Read MoreInnovation – New tool to efficiently drill lifting lugs. Lifting lugs are a critical component of the assembly and installation of any large equipment, modules or structures. However, when the fabrication of these components began costing man-hours the team looked to make a change. Faster and Safer! Bonus d’Inscription : Les Meilleurs Casinos pour 2025…

Read MoreIt wasn’t too long ago that the equipment group completed, assembled and packaged, by hand, their inspection sheets and auxiliary information, then batch submitting their inspection report packages. It then took time for the package to be received, sorted and reviewed. Only once this process took place could equipment be schedule for repair, maintenance or…

Read MoreThe Mity Mite Pipe Puller Built In The USA by JV Driver Fabricators The innovative Mity Mite is a one-of-a-kind expansion joint compression tool used for pipe pulling and the installation of concrete pipe, concrete box culverts, precast concrete steel cylinder pipe, and ductile iron pipe. It is designed, manufactured, and tested out of our…

Read MoreAt JV Driver we believe in “Thinking Different and Building Better” in everything we do, this includes going one step further and bringing innovation to our AWP training, by using practical applications on top of our industry standard work. This was the idea behind our Aerial Work Platform (AWP) obstacle course, which allows our employees…

Read MoreJV Driver Fabricator’s “single site, single source” model benefits our clients in two important ways: by one, giving them the best value possible and two, creating schedule certainty. In the Alberta market, with module and pipe projects (most module yards do their own pipe fabrication, but not steel), their products have to be transported to…

Read More